About Us

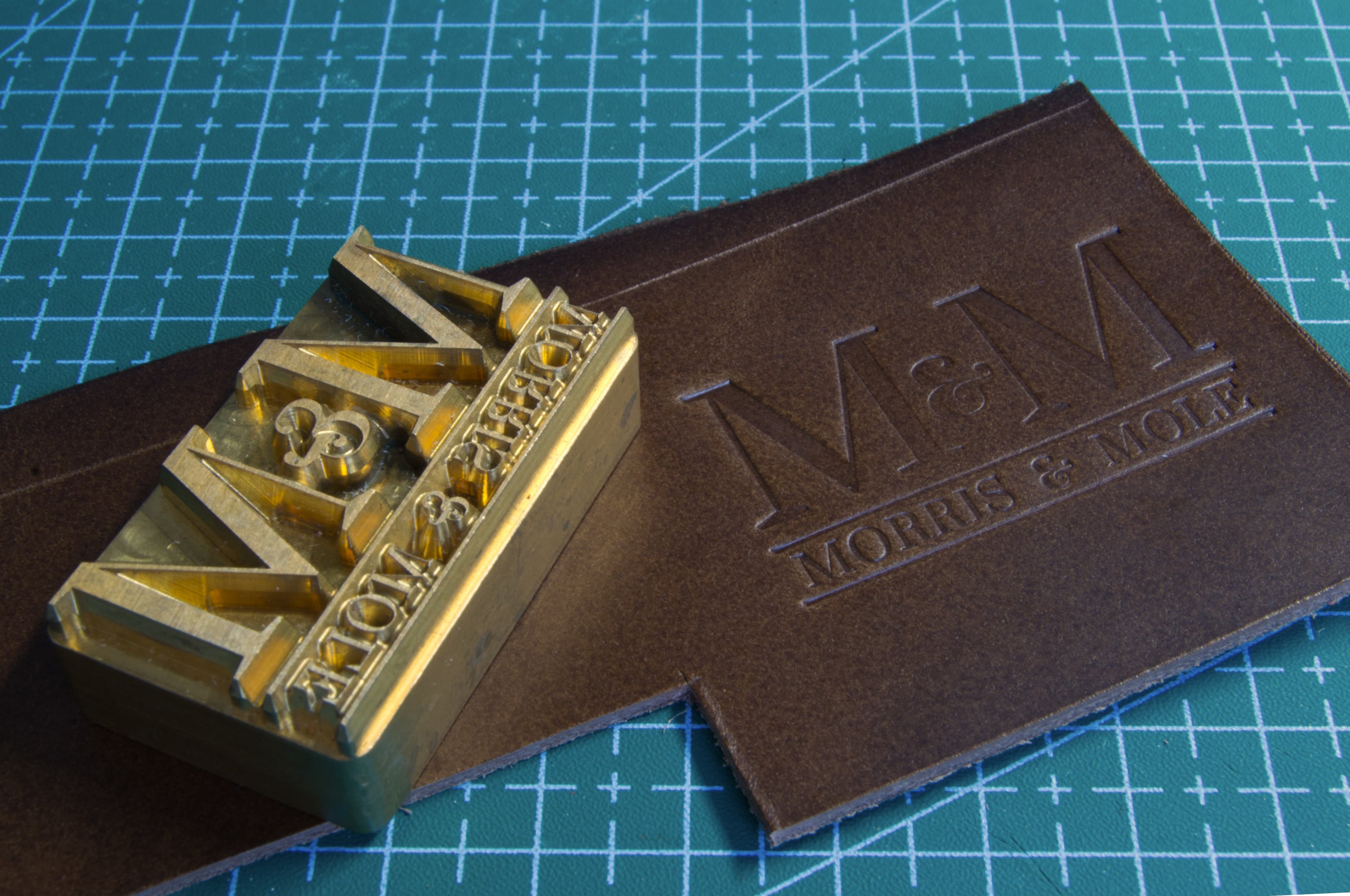

Morris and Mole was established in 2024 in Wheelton, a village in Lancashire. It is here that we hand cut, stitch and finish all of the leather products that you can find in our store.

Holly, Owner

"I’m Holly, the owner and creator of Morris & Mole. Previously my career was in science, but after completing a PhD in Cancer Sciences I decided it was time for a change. I’ve always loved crafting and creating – I wanted to see if I could turn that passion into a small business.

Our inspiration comes from close to home. Morris & Mole is a combination of the name of our Irish Setter Morris, a regular resident of our workshop, and my maiden name ‘Mole.’ Our wallet and purse names are similarly drawn from species of trees that we encounter in local woodlands - a nod to the fact that trees are essential for the production of vegetable-tanned leather.

My aim is to design products that look and feel special, made with care using responsibly sourced high-quality materials."

Traditional Techniques

All Morris & Mole products are designed and cut by hand. They are then carefully sewn together with a traditional saddle stitch using waxed thread. All edges are then dyed and burnished for a smart finish, before a final treatment with our Beeswax, Cocoa Butter and Almond Oil Leather Balm.

Sourcing Our Leather

At Morris & Mole understanding the origin of our raw materials is important to us. We source all of our leather from the Conceria Walpier tannery in Tuscany, a region widely considered to be the leather production capital of Italy. Skilled artisans in this area have been tanning leather since the middle-ages and specialise in the production of high-quality vegetable-tanned leathers.

This age-old technique utilises plant-based tannins from the bark, roots and leaves of trees such as birch, chestnut, willow and oak. It is a slow process which cannot be rushed. This results in a fine leather which retains its absorbency and mouldability, maturing with the passage of time to develop a unique patina and mould to its contents.

The family-run Conceria Walpier tannery is a member of the Genuine Italian Vegetable-Tanned Leather Consortium, which holds its members to high standards of quality, sustainability, and environmental and social responsibility. All the hides used by Consortium tanneries are by-products of the meat industry which would otherwise be destined for landfill, and come from cattle protected by EU animal welfare regulations. To prevent water pollution, treatment of waste from the tanneries is also tightly controlled, and many of the by-products are salvaged and used in other sectors such as in agriculture and construction.

The vast majority of leather goods on the market today are made from chrome-tanned leather, which uses chemicals such as chromium sulphate to tan hides. This process is quicker and more automated, but produces toxic by-products containing chromium and lead. These can pollute waterways and pose a significant threat to local ecosystems, especially in developing countries to which the production of chrome-tanned leather is often out-sourced. So called ‘vegan’ leather is often touted as an alternative, however this is typically derived from non-renewable petrochemicals, requires many chemicals in its production, and is non-biodegradable at the end of its useful life.

Ultimately there is an environmental cost to any material, but by carefully sourcing our vegetable-tanned leather from responsible tanneries we can help to reduce this as far as possible. By practicing conscious consumerism and investing in higher quality, timeless designs which will be used for years to come, we can all do our bit.